Combined incineration gasification and melting treatment technology for hazardous waste with three-dimensional graded air supply

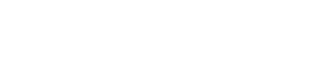

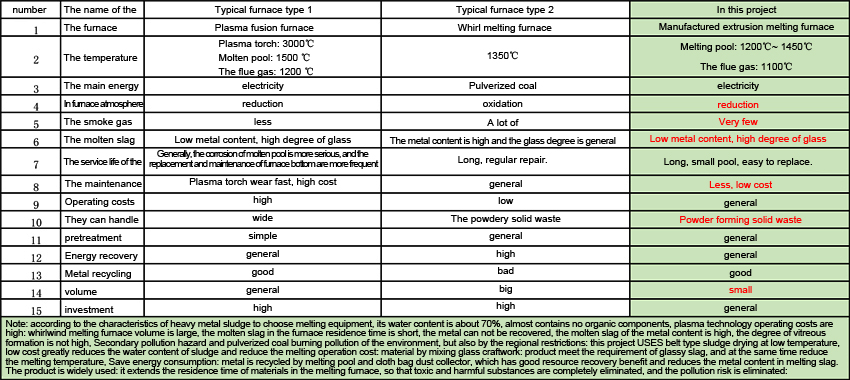

Process flow chart

Pretreatment section:Sludge after sorting, drying, crushing, batching, mixing, granulation, through the quantitative feeding device into the melting furnace.

Melting and incineration section:Melting furnace, slag removal machine, ladle, high greenhouse, will maximize the organic matter in the material incineration.

Exhaust gas purification section:The harmful substances in the flue gas are removed by quenching, dust removal, deacidification, fog removal and reheat of flue gas, so as to achieve the purpose of flue gas purification.

Hazardous waste incineration ash slag melting slag

Technical highlights:

◆ Good adaptability of waste: low quality heavy metal sludge (about 1% metal content, about 80% water) can be treated;

◆ Small energy consumption: the heat source is electricity, is clean energy, high efficiency (up to 80%), more energy saving;

◆ Low cost of tail gas treatment: little amount of exhaust gas production, low investment cost of tail gas purification equipment, low operating cost;

◆ Low maintenance cost: the furnace body is light and small, the operation is flexible, the temperature is controllable, the loss is small;

◆ minimal waste water production: low waste water treatment costs;

No solid waste generation: no need for landfill;

◆ Alloy can be recycled: resource reuse, considerable profit;

◆ Cloth bag ash can be recycled: resource reuse, considerable profit;

◆ Recyclable glass sand: the formation of other inorganic vitreous slag, as a product widely used, green material.

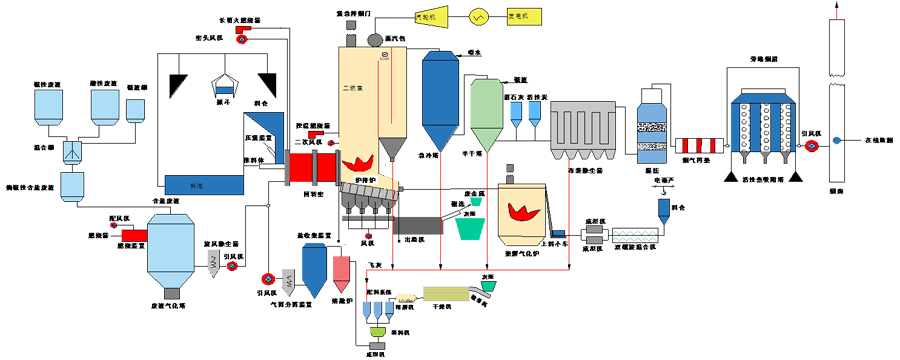

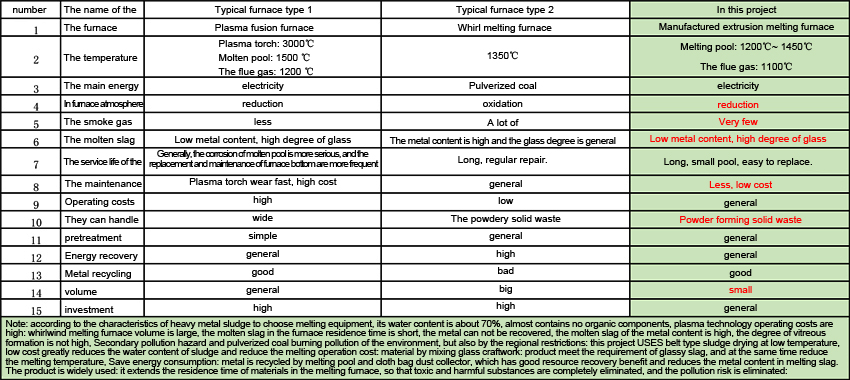

Technology to compare:

Web site to

Web site to