A new integrated industrial sludge dry-incineration/carbonization resource treatment technology

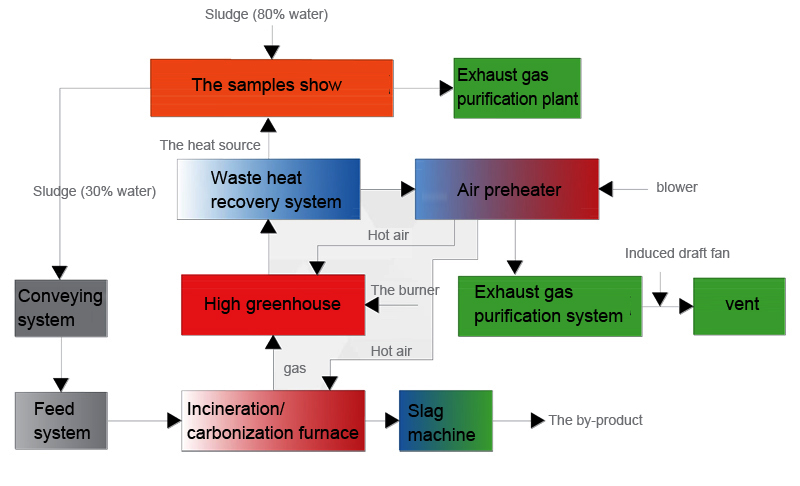

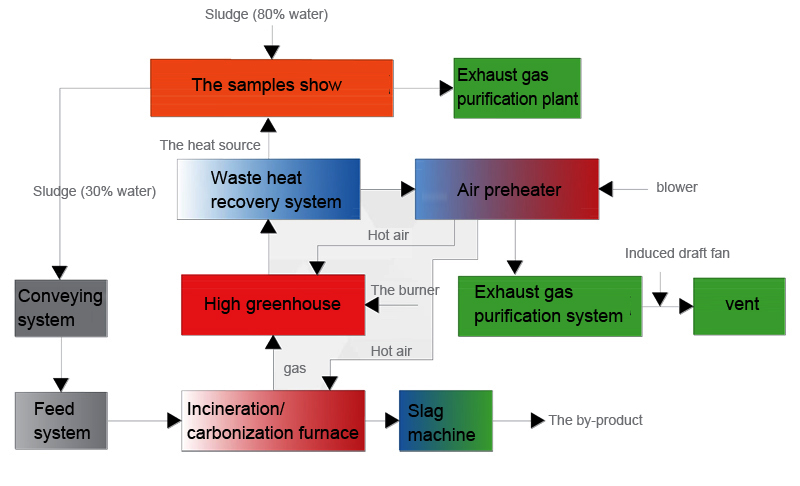

Process flow chart

Technology is introduced:

★Storage and drying of sludge

Water 80% sludge, directly discharged into the tank by the amount of the transport vehicle, feeding process will not produce dust; The storage tank is slightly negative pressure, and the transport vehicle is discharged and the sludge is dried. The whole process is completed in a closed environment without exhaust gas leakage. The high temperature flue gas after incineration/carbonization is heat exchanged through the waste heat utilization system to supply heat for sludge drying, which is easy to control temperature and directly reduces the drying cost. After starting the machine, the whole process can be automatically dried according to the set requirements, without manual intervention, just regular inspection can be done, with a high degree of automation

★Incineration or carbonation of sludge

The upper bin of the incineration/carbonization furnace has the function of anti-blocking vibration and weighing measurement. The outlet of the bin is connected with the inlet equipment of the feeder, and the outlet of the feeder is connected with the feed port of the incineration/carbonization furnace. The feeder will continuously and evenly send the materials into the incineration/carbonization furnace for pyrolysis according to the set quantity. Sludge in the incineration/carbonization furnace from front to back after drying, partial combustion, pyrolysis and gasification, into the slag-discharging machine to complete the incineration/carbonization of sludge; Incineration/carbonization furnace adopts electric heating, which is a clean energy advocated by the state. The heating is fast and the temperature control is simpler. The sludge can be ignited quickly into the state of incineration/carbonization. After the sludge is incinerated/carbonized, the organic matter is incinerated and the heavy metals are passivated, which is not easy to precipitate. The reduction amount reaches more than 85%. It can be widely used as municipal roads, building materials and soil amendments.

★Waste heat utilization and waste gas treatment

High greenhouse Settings after burning/carbide furnace, sludge incineration/carbide furnace under the action of high temperature, sludge moisture and volatile matter in gaseous form through high temperature flue into high greenhouse, high greenhouse burning chamber, the volume is larger, the internal is adiabatic type design, is equipped with temperature control burner and blower, can satisfy the flue gas under the high temperature of 850 ℃ >, residence time > 2 seconds, The organic matter in the flue gas can be completely burned, and the formation conditions of dioxins can be destroyed. The high temperature flue gas at the outlet of the high greenhouse enters the waste heat utilization system and the air preheater for heat exchange and cooling, and then is purified by the tail gas purification system, and finally is sent to the exhaust pipe by the induced draft fan for discharge.

Equipment characteristics and technological methods of advanced and applicability:

· In this project, sludge is dried at the same time of sludge storage, which saves construction land; 2. No high temperature and high heat method is adopted for drying, saving energy consumption, long service life and no risk of scald; 3. At the same time, the sludge quality is reduced and the calorific value of sludge is improved, which greatly reduces the cost of sludge incineration/carbonization.

· The starting energy of the incineration/carbonization furnace of this project is electricity, which belongs to the clean energy advocated by China. The temperature rise of the incineration/carbonization furnace is fast, and the material quickly reaches the ignition point in the incineration/carbonization furnace. The material can meet the requirements of the incineration/carbonization temperature through its own combustion, and stop or reduce the electric heating supply at the same time to save the cost of incineration/carbonization; In the incineration/carbonization process, a small amount of wind is supplied, and little nitrogen oxides are produced at high temperature. According to the characteristics of sludge, sludge incineration treatment or carbonization treatment can be selected on the same system, which has a wide range of treatment and wide application of products. Incineration/carbonization furnace has the characteristics of fast heating, high efficiency, small volume, less heat dissipation loss and low energy consumption; According to the material requirements, the temperature in the incineration/carbonization furnace can be freely controlled at 550℃ ~ 950℃, the residence time of the material is > 30min, the volatiles enter the high greenhouse with the flue gas, the organic matter in the sludge is incinerated, the by-products are discharged continuously, the heavy metals are passivated, not easy to dissolve and non-toxic and harmless, and the by-products are widely used.

· After the incineration/carbonization furnace, there is a high greenhouse with large volume, adiabatic design and temperature control burner, which ensures the high greenhouse temperature > 850℃ and the residence time of flue gas at high temperature > 2 seconds. With air supplement device, through the swirling air, so that the flue gas and air fully mixed contact, combustible burning, while destroying the formation conditions of dioxins. ? Flue gas provides heat for sludge drying through the waste heat utilization device, and the flue gas after cooling is purified by the tail gas purification system and discharged to the standard. Small amount of smoke, low pressure of tail gas treatment.

· This project is mainly aimed at incineration/carbonization of organic sludge, so as to make it harmless, reduce, recycle and save energy in production. The selected equipment and process suitable for production floor and dispose waste unit, cover an area of an area small, no storage cost and transport cost, avoid the risk of the transport process of secondary pollution, comparing the present centralized collection of sludge landfill disposal ways and centralized collection or carbide sludge incineration scheme proposed, production units directly to the court to scrap disposal way is more suitable for treatment of solid waste in our country, The new integrated sludge dry-incineration/carbonization system features stable operating conditions, wide treatment range, low investment, low operating cost, more thorough treatment and disposal, and more outstanding recycling benefits

Technical highlights:

◆ wide adaptability of waste: municipal sludge, industrial sludge can be treated;

◆ Small energy consumption: the heat source is electricity, is clean energy, high efficiency (up to 80%), waste heat utilization, self-sufficiency, more energy saving;

◆ Low cost of tail gas treatment: less waste gas production, low investment cost of tail gas purification equipment, low operating cost;

◆ Low maintenance cost: easy installation, flexible operation, temperature control, small loss;

◆ minimal waste water production: low waste water treatment costs;

◆ No solid waste generation: The product carbon content is controllable, the metal is passivated, non-toxic and harmless, the product has a wide range of applications, no need for landfill;

◆ Metal ash can be recycled: Resources reuse, considerable profits;

◆ Flexible process control: the same system can choose incineration or carbonization two processing modes.

◆ High degree of automation: PLC design, flexible operation, low labor intensity, safer;

◆ The project construction period is short: 9 ~ 12 months, small area, combined type, small area, small environment constraint.

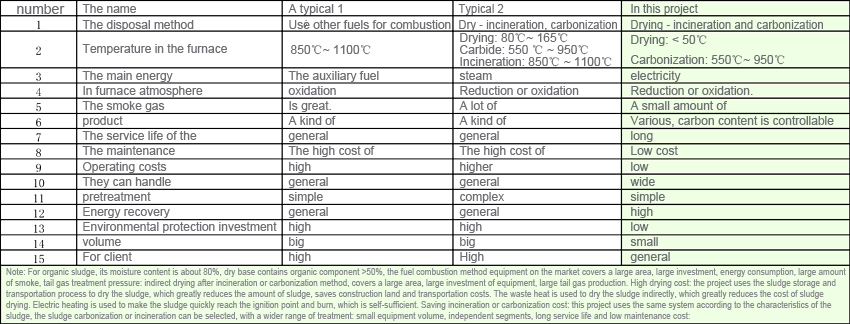

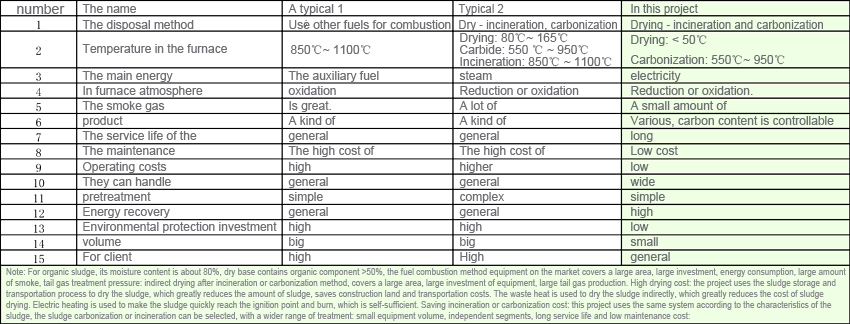

Technology to compare:

A new integrated dry-incineration/carbonization resource treatment technology for printing and dyeing sludge

Differences with municipal sludge disposal methods

★pretreatment of printing and dyeing sludge

Printing and dyeing sludge contains a variety of harmful heavy metals, are defined as hazardous waste, must according to the set of after drying of printing and dyeing sludge quantitative reagent addition (reagent adding quantity should be according to the actual dyeing process of sludge after setting element analysis), after mixing, into the granulator granulation process, then after pretreatment of printing and dyeing sludge into burning/carbide furnace.

★Design principle of incineration process

Different from municipal sludge, printing and dyeing sludge incineration or carbonization disposal should conform to the incineration process of hazardous waste. Its high greenhouse temperature requires > 1100℃, and the residence time of flue gas in the high temperature period of 1100℃ > 2 seconds. The flue gas after heat exchange and cooling must be quench by water spray, and the flue gas drops from 500℃ to below 200℃ for a time less than 1 second. The exhaust gas purification should be based on the actual process of the printing and dyeing factory sludge for element analysis after matching.

★Metal recycling

After printing and dyeing sludge by adding medicament, which is beneficial to its internal metal in the process of burning or carbide volatilization, most metals from the material into the flue gas at this time, most of the metals by bag filter after collection utilization of tail gas treatment system, a byproduct of burning at the same time or after carbonization, the metal content is greatly reduced, the trace metal was passivation, nonpoisonous and harmless, It can be widely used as building materials and soil amendments.

Web site to

Web site to