Eddy current self-heating rotary kiln

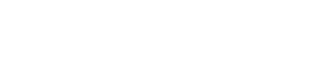

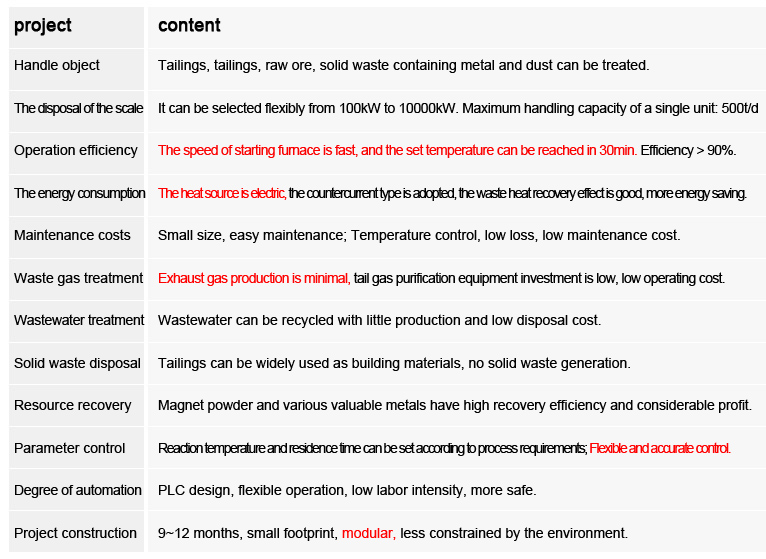

Production flow chart of eddy current self-heating rotary kiln equipment

Technology is introduced:

Will tail slag, tailings, undressed ore and metal containing slag and dust, by adding activator and reducing agent such as ingredients, into the inductance vortex self-heating type high temperature rotary kiln, the kiln preheating dry, heating calcining, activation, reduction, magnetization and a series of physical and chemical reaction, the magnetization slag after heat exchange cooling from a preheater, After grinding and magnetic separation, the metal and sintering slag are separated and collected respectively. All kinds of valuable metals in the exhaust gas are collected by means of pulse dust collector and water curtain washing. Recycling of metal and recycling of sintering slag as building materials.

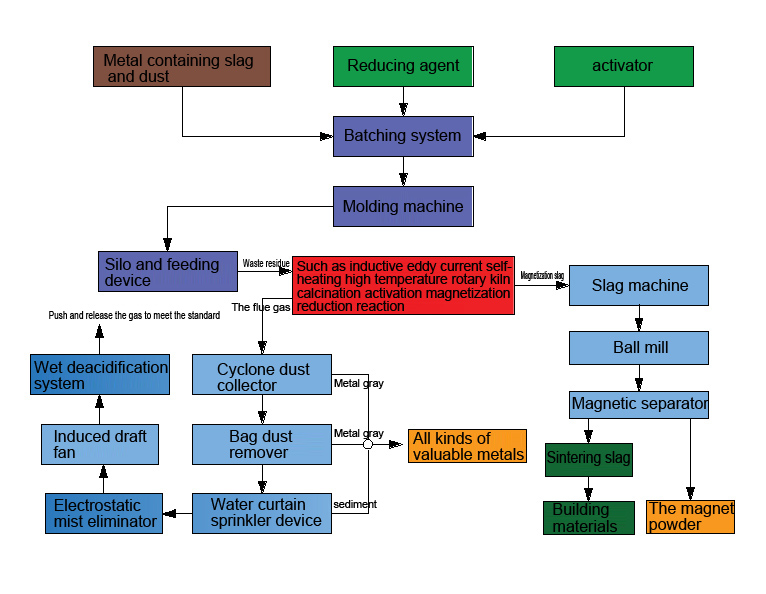

Technical characteristics:

· With electricity as the heat source, it belongs to the clean energy advocated by the state and has a very small amount of smoke.

· Inductive eddy current self-heating type, fast starting speed, 30min can reach the process temperature requirements.

· PID wireless temperature measurement closed-loop control system, accurate temperature control, high metal recovery efficiency.

· 1200 alloy furnace core, working temperature 1200℃, still has high strength, corrosion resistance characteristics.

· Modular design, convenient assembly, short construction period.

· Flue gas countercurrent design, more prominent energy-saving effect.

· It can work continuously for 24 hours, and the annual running time is > 300 days.

The scene pictures:

Project information:

Metal recovery efficiency:

ailings of lead and zinc smelting (jarosite slag)

Zinc: 93%; Ag: 75%; In: 90%;

Conversion rate of Fe2O3 to Fe3O4:88%.

Gold smelting slag (cyanide slag)

Au: 93%; Ag: 77%; Zinc: 90%; Pb: 92%;

Conversion rate of Fe2O3 to Fe3O4:85%.

Steel smelting tailings (blast furnace ash)

Zinc: 93%; Pb: 98%;

The conversion rate of Fe2O3 to Fe3O4:87%.

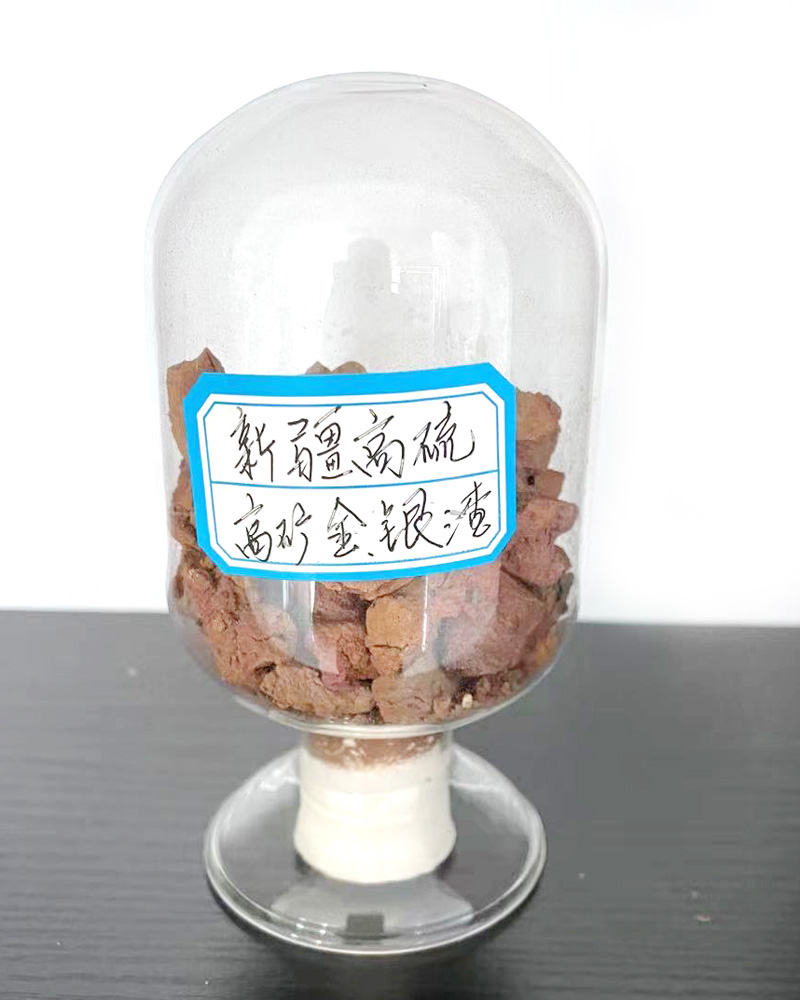

Sulfuric acid smelting slag

Au: 95%; Ag: 73%;

The conversion rate from Fe2O3 to Fe3O4:88%.

Organic sludge (municipal sludge)

Pb: 99%; Ni: 87%; Zinc: 93%

80% water-containing sludge after dry incineration reduction rate: 95%.

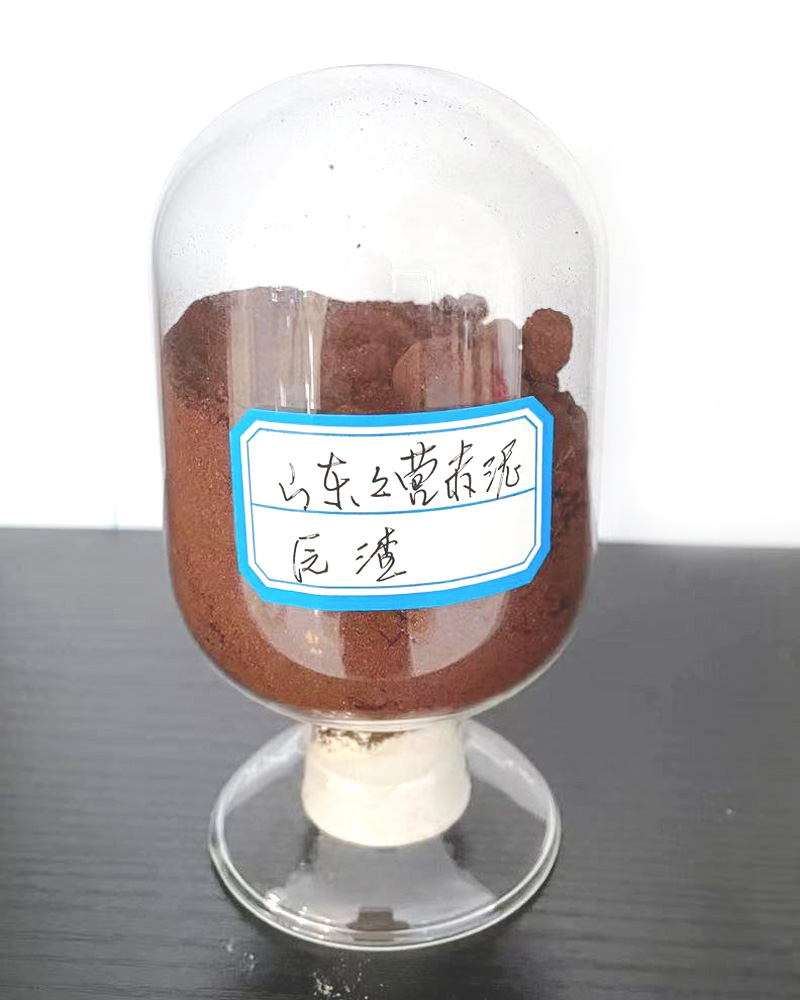

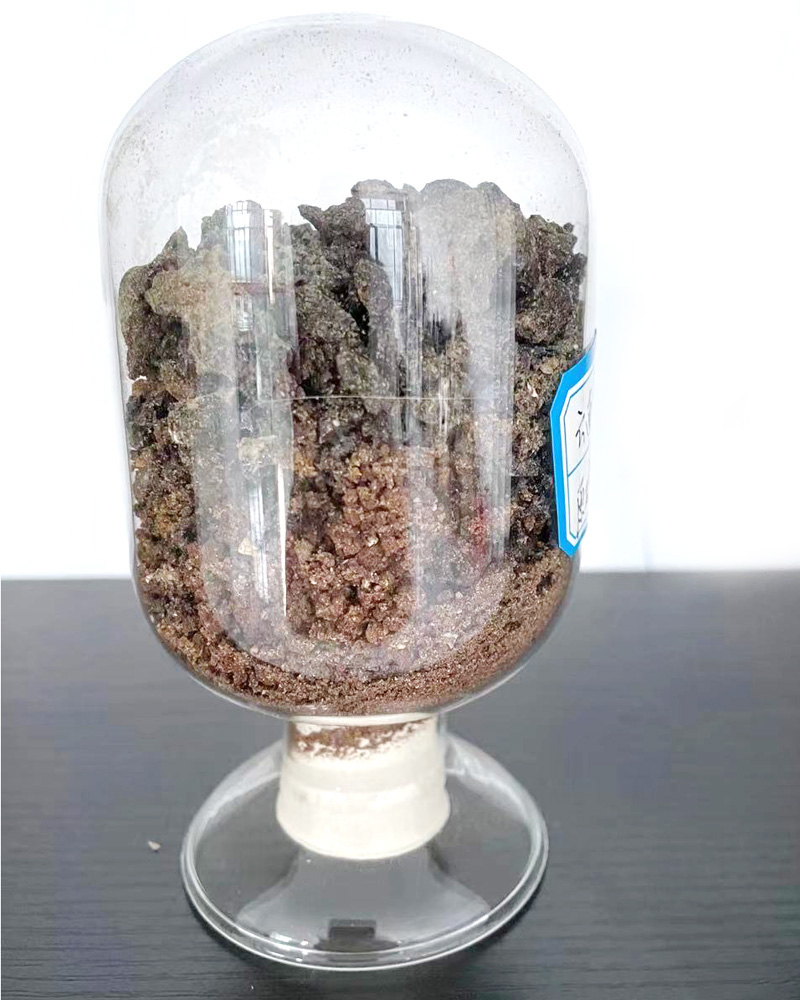

The samples show:

Test report:

Web site to

Web site to